|

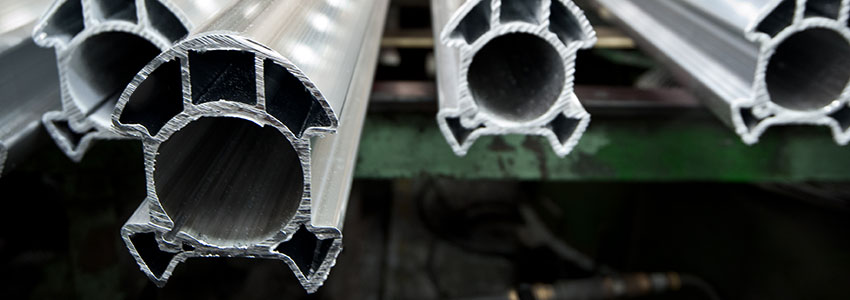

Aluminum Extrusion Design Tips

Aluminum extrusions have very few design restrictions - the exact shape you require can usually be manufactured without compromise. Superior designs utilize some of the many unique features of extrusions while increasing productivity and decreasing scrap and labor costs.

When designing your extrusions, consider the end use of the part and any required machining or fabrication. The following tips may improve your extrusion designs:

- Unequal wall thicknesses are possible; however, uniform walls are preferable.

- Extrusion tooling for solid profiles is less expensive than tooling for hollow shapes.

- Small radii on corners are better than sharp edges.

- If possible, maintaining symmetry can improve the production of your extrusion.

- Designing grooves or ribs into your extrusion can minimize scratches or act as stiffeners.

- Hollow or semi-hollow profiles are ideal for intricate extrusions.

- Near-net shapes can reduce or completely eliminate further machining.

- Deep slots or grooves can be extruded depending on their size.

- Make assembly easier by including screw ports and fastening points in your extrusion.

Checklist What information does your extruder need?

Your extruder wil be able to serve you better if you supply some or all of the following information:

- A dimensioned sketch or drawing (CAD file if possible), or a sample of the part.

- Details of the extrusion's proposed function.

- The alloy and temper required. If unknown, the physical requirements of the part.

- Any special dimensions or tolerances that may be needed.

- Possible types of finishes and an indication of any exposed surfaces.

- A description of any proposed secondary fabrication: drilling, mitre cutting, milling, etc.

- Type of packaging required.

- An estimate of the prototype and production quantities.

- The cutting lengths required.

- Time frame for quote and delivery of finished product.

|

|

| Home | About Us | Back To Technical Library | Contact Us |

|

Copyright © 1996-2010 JobShop.com. All Rights Reserved. General or Technical Questions? E-mail support@JobShop.com |