|

This technical information has been contributed by

Northeast Mold & Plastics

Click here to find suppliersTwo-Shot Plastic Injection Molding

What is it?

Producing two color or two component injected molded parts from two different thermoplastic materials in one process, quickly and efficiently:

- Two-shot plastic injection molding, co-injection, two-color and multi-component molding are all variations of an advanced molding technology

- Combining hard plastics with soft materials

- Two step process performed during a single press machine cycle

- Consolidates two or more components thus eliminating additional assembly costs

The technology of injection molding continues to become increasingly sophisticated. Up-to-date fabrication technology allows processors to produce injection molded parts from two different thermoplastic materials. By combining these different materials with the ever-improving molding technology, complex functional parts can now be produced economically and efficiently in massive quantities.

The materials may differ in polymer type and/or hardness, and can be fabricated from molding techniques such as dual injection molding, two-shot molding, two color molding, two component molding and/or multi-shot molding. Whatever its designation, a sandwich configuration has been made in which two or more polymers are laminated to take advantage of the properties each contributes to the structure. The thermoplastic parts from these moldings offer excellent performance characteristics and reduced cost.

How Does it Work?

- Two shot machine with two independent injection units

- Molding one part using two different materials or colors

- Two cavity mold (one + one)

- First material injected into first cavity, mold opens and rotates to second cavity position, mold closes and second material is injected. After sufficient part cooling, the mold is opened and the part is ejected.

- Critical factors:

- material(s) melt temperature

- mold wall temperature

- injection speed

- delay time between injections

- component part temperature

The two-shot plastic injection molding process requires a machine with two independent injection units, each of which shoots different material. The first material is injected through a primary runner system, as in a normal injection molding cycle. During the injection, the mold volume to be occupied by the second material is shut off from the primary runner system. The mold is then opened and the core plate rotated 180 degrees. The mold is again closed and the secondary runner system is connected to the volume to be filled. After sufficient part cooling, the mold is opened and the part is ejected.

The two-shot process can also be accomplished with an indexing system (a round table rotating around a horizontal axis) with a primary and secondary station. While the first injection is accomplished at station #1, the second injection is accomplished at station #2. Each injection station is run by an independent injection unit. This allows injection speeds and pressures to be controlled for each material being utilized.

What are the Benefits?

- Lower part cost: savings in production, handling, assembly and inventory

- Simplifies the production process with higher quality fabrication

- Eliminate secondary operations

- Improves integrity of the product

- Enhances product features and appeal: tactile, ergonomic, cosmetic

- New design possibilities

- Packaging applications where a secondary color is desired to give prodcuts a unique appearance

- Added features to improve part functionally:

- multiple colors

- soft touch surfaces

- gaskets and seals

The real payoff of two-shot plastic injection molding of thermoplastic materials is an economic one. Parts of two different materials can be fabricated with the speed, efficiency and economy of thermoplastic processing. This eliminates the labor-intensive secondary operations used for so many years and replaces them with high-speed automated operations, to yield a more consistent, higher quality fabricated part at a significantly lower cost.

Two Shot Molding is ideal for:

- Soft touch handles, grips and other components

- Multi-color buttons, switches and knobs

- Movable segments or components

- Water shield and protection

- Caps and enclosures

- Back-lit buttons, dials and other instrumentation products

- Drop protection

- Vibration and noise dampening and isolation

If you would like additional information on two shot molding, we suggest these links . . . .

Arburg

Ticona

Injection Molding Magazine

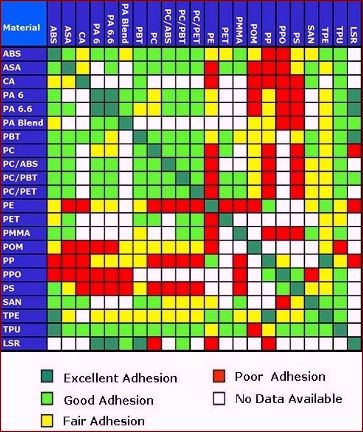

...Download a PDF of this Material Compatibility ChartTwo Shot Material Compatibility Chart

|

|

| Home | About Us | Back To Technical Library | Contact Us |

|

Copyright © 1996-2010 JobShop.com. All Rights Reserved. General or Technical Questions? E-mail support@JobShop.com |